flexographer's Conference 2024

- ABOUT EVENT -

Venue of the 2024 Flexographers' Conference

Warsaw Plaza Hotel is a 4 - star hotel distinguished by modern design, excellent cuisine, and spacious conference rooms providing ideal conditions for organizing business meetings and large conferences for over 400 people. Warsaw Plaza Hotel also offers excellent accommodation with 292 luxuriously appointed rooms. The staff ensures that each guest will relax and unwind in these comfortable interiors.

Address and directions to the Conference venue

The hotel is located at 5 Łączyny Street, 02-820 Warsaw. Its close proximity to the A2 highway exit ensures easy access from all over Poland and beyond. The airport is just 4 km away. The hotel parking provides 80 free parking spaces. Additionally, on level -1, there are 60 monitored, garage spaces, including 2 stations for charging electric cars. The cost of underground parking is 55 PLN gross per day, and electric car charging is 100 PLN. Within 500 - 1000 meters, there are 2 additional hotels for those who may not find available rooms at the Conference venue.

Program of the Flexographers' Conference 2024

We will soon present the Conference Agenda. The agenda will cover topics related to flexographic technology in both wide and narrow web segments, as well as corrugated cardboard. A workshop addressing common issues in flexographic printing, complete with a Q&A session, is scheduled. Additionally, there will be a presentation on Extended Color Gamut (ECG) printing. Stay tuned for more details!

INVITED EXPERTS

Stefano d’Andrea

Stefano is an industrial graphic expert. Since 1989 he dedicated his entire professional activity to the flexographic process, from design and prepress, to plate making and printing. During his career in the flexo industry he has covered several roles, including technical support to sales, product management, business development, education and technical training. Since 2017 he is dedicated exclusively to technical education in the flexographic process and consultancy as an independent professional. Stefano manages the flexo.expert and flexo.training websites and carries out teaching activities both independently and in collaboration with Italian and foreign technical institutes. He is a member of FTA USA with which he obtained the title of Level III Certified Implementation Specialist according to the FIRST (Flexographic Image Reproduction Specifications & Tolerances) method, executive board member of the Flexo Quality Consortium and of the FIRST Leadership Committee. He actively contributes to the activities of ATIF (Italian Technical Association for Flexography) and FTA Europe. He is a member of TAGA Italia and contributes to the activities of the ISO TC 130 group.

Dr Kai Lankinen

Dr. Kai Lankinen has 20+ years experience in package printing. He founded Dr. Lankinen Graphic Innovations Ltd in 2022 to consult global package printers and brand owners to adopt better efficiency and sustainability trhough expanded gamut printing (ECG). He is also a co-owner and former CEO of a leading Nordic repro house and founding member of the Global Premedia Network. Previously, he was a factory manager at a flexible packaging printing company and was a founder member and ex-chairman of the Finnish Packaging Printing Committee. In 2021, he published his doctoral thesis, “Evaluation of Expanded Gamut Printing in Flexography”.

M.Sc. Małgorzata Szczotka

Małgorzata Szczotka is a G7® Expert Idealliance specializing in the implementation of color management at all stages of the graphic reproduction process. She obtained her expertise at the Swedish institution, Brobygrafiska. For the past 13 years, she has been leading Color Management Consulting, collaborating with specialists at each stage of production such as prepress, CTP, printing, ink mixing, and quality control. Together, they provide comprehensive standardization and optimization services for the graphic reproduction process. CMC has standardized over 28 flexographic printing facilities, comprising more than 72 printing machines. CMC's implemented actions aim to standardize the printing process in terms of color consistency with international and industry standards, as well as FTA and ATIF industry recommendations. The initiatives also involve digitizing physical color standards and improving the digital flow of spot color information between the ink mixing room and the printing hall. All of these efforts are directed towards ensuring optimal production efficiency, minimizing waste, and reducing setup time.

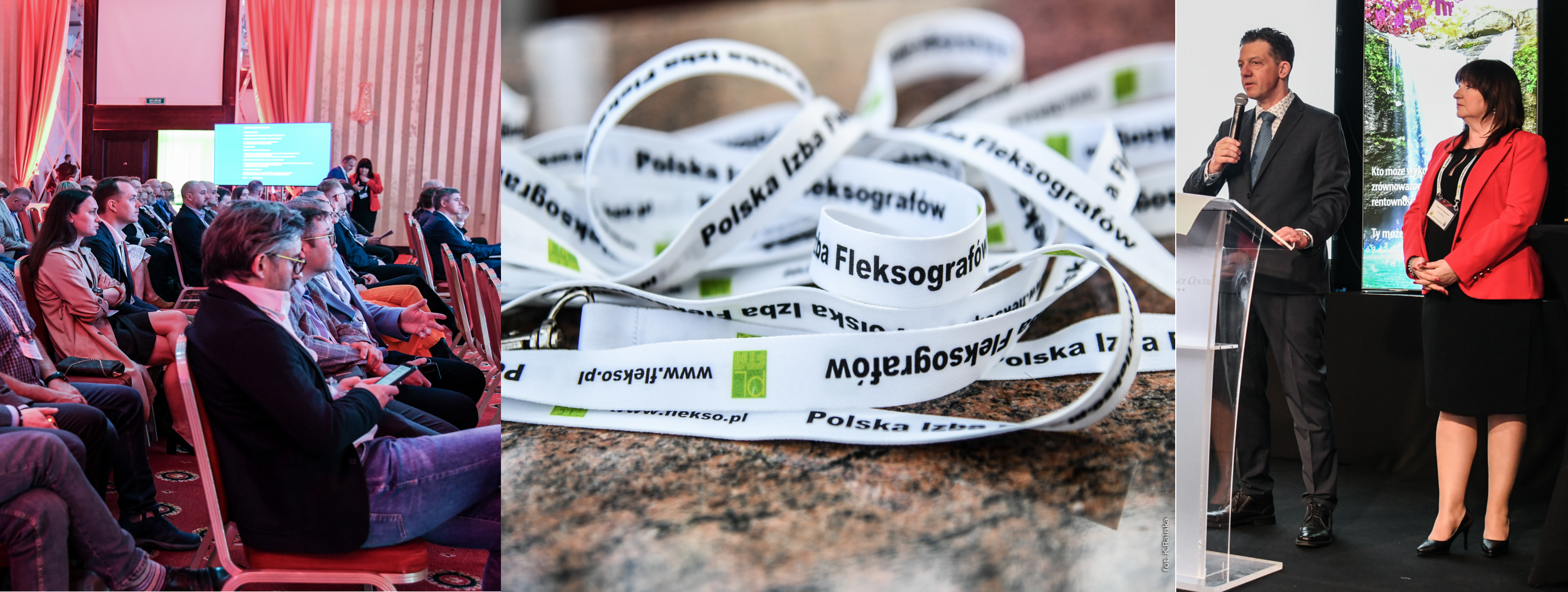

Previous edition

During the 3-day celebration of the annual Flexographers' Conference, nearly 300 participants visited the Mazurkas Hotel in Ożarów Mazowiecki. Among the sizable group of attendees, almost 100 represented flexographic printing companies and cardboard packaging manufacturers. The most numerous group consisted of suppliers, including sponsors such as Sun Chemical, Uteco, Scorpio, and AVG Service. Mark Andy was the technological partner, and Bank Pekao was the supporting partner.